Fluid Drainage & Management in Food & Beverage Manufacturing Facilities

Proactive fluid management in food manufacturing facilities is essential for efficient and safe operation of the facility.

The various components/ elements of a hygiene critical manufacturing facility must be considered and designed in conjunction with each other. The two primary elements of factory drainage tend to be the flooring and the actual drains:

- Floors – need to be set with falls to drains. Typically, a fall of 1 in 100 is needed for consistent flow to drains without pooling or puddles. While a greater fall increases flow to drains, it can be detrimental when wheeled trolleys and forklifts are used.

Careful surveying of the floor and existing drainage system will greatly help with working out the best way to ‘fall’ the floor to the final drains.

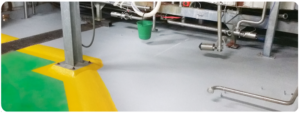

At times, local ‘water-sheds’ formed using high strength epoxy mortar can provide area specific surface water guidance – see image of hump-bund in Safety Yellow, directing waste water away from a foot path and towards an existing strip drain.

– .

. - Drains – there are endless options available for type and style of drain, from point (gullies), to strip, and slot drains, each with their own particular strengths and weaknesses.

- Point drains or gullies – these are often the best solution for confined rooms where all of the waste water can be drained to a reasonably central point.

- Slot drains – these are channel drains that allow reception of waste water along a wide front, but are less visible than conventional strip drains. Two negatives that need to be considered are that by nature, the inside surfaces of the drain aren’t easily accessed for cleaning, and also, the volume of fluids that can be conveyed tends to be limited.

- Strip drains – these channel drains have proven themselves over decades of use in the food and beverage, and pharmaceutical manufacturing sectors. Available in a very wide range of configurations – width, depth, and length – and with a range of available grates, strip drains will often be the logical answer.

Separate to the production area, areas that need careful fluid management are the CIP station or room, the trade waste area, and bunded zones such as for storage of chemicals, fermenting, etc.

Bunded Storage Areas

Bunds are designed to contain spillages and leaks of liquids used, stored, or processed above ground and to facilitate clean-up operations. As well as being used to prevent pollution, bunds are also used for fire protection, safety of workers, and product recovery.

There are multiple different types of bunds:

- Ramp bund

- Hump bund

- Square Bund

The net capacity of a bunded compound in a storage facility should be at least 120% of the net capacity of the largest tank. Take into consideration the capacity displaced by other tanks within the same bunded area and any foundations. Treat interconnected tanks as a single tank of equivalent total volume for the purposes of the bund design criteria.

For flammable liquids, bund capacity should be at least 133% of the net capacity of the largest tank. If an automatic fire sprinkler system is installed in or over any bunded tank or drum storage compound, the capacity of the bund should be increased either by a volume equal to the output from the sprinkler system for a period of at least 20 minutes, or to 133% of the capacity of the largest tank, whichever is greater.

Our bunding solutions are constructed out of impervious materials to ensure no liquid can seep through the bund walls or floors.