While the Australian New Zealand Food Standards Code sets out the requirements for flooring in food manufacturing facilities, it spends little time exploring the available flooring solutions, and whether they meet the standards or not. We’ve put together the below guide to assist food and beverage manufacturing facilities in choosing the right flooring solution for your needs. There is no order in the below flooring solutions, they are just listed out one by one.

1. Ceramic Tiles

Ceramic tiles are highly durable and excellent for heavy traffic. Their impact resistance is good, therefore meaning their life is long. In clause 10 (2) (a), it specifies that floors must be able to be effectively cleaned. This is the biggest downfall when it comes to ceramic tiles. While the grout requirements specify an epoxy grout, the cleaning is still difficult and regular maintenance is needed so they don’t harbour microbes, dirt and grease. Another consideration is that they are, however, relatively expensive and require a long duration for installation.

2. Quarry Tiles

Quarry tiles are, like ceramic tiles, highly durable and can stand up to high traffic loads. They provide sufficient durability to withstand the type of cleaning operations in food manufacturing facilities. While their durability is a bonus, similarly to ceramic tiles, the biggest downfall is the grout. Stringent cleaning routines must be upheld in order to ensure that bacteria does not grow in the grout lines. Again, installation time is long, and long term cost for installation, maintenance, and cleaning is high.

3. Epoxy Resin

Epoxy resins have a fast installation time and are durable. High solid epoxies provide good protection against acids and alkalis. The finish lends itself to being easily cleaned, although a higher non-slip film can make it slightly more difficult to clean (read more here). Epoxy resins are ideal in clean rooms or areas with maximum hygiene requirements that have light traffic. Applied in an area with heavy traffic, it will have a much shorter life than tiles or polyurethane cement. They also don’t handle cold or thermal shock conditions very well, making them unsuitable for various applications in food manufacturing facilities. If applied in the right area, long term cost is small. However epoxy resins do not stand up to heavy traffic, therefore cost in such a scenario is high.

4. Polyurethane Cement

Polyurethane cements have a long service life. They have good resistance to thermal cycling, and excellent chemical resistance, to nearly all acids in food manufacturing facilities (including lactic acid). Their finish is similar to epoxies, however, having a naturally rougher texture allows it to be more easily cleaned, unlike epoxies. Polyurethane cements have greater resilience and elasticity than epoxy resins, making them more resistant to scratching and marring. The elasticity makes this type of floor suitable for freezers where storage temperatures may reach -30°C. Upfront cost of a polyurethane cement system is typically higher than most other applications, however the longterm cost is much smaller due to the durability and longevity of the system.

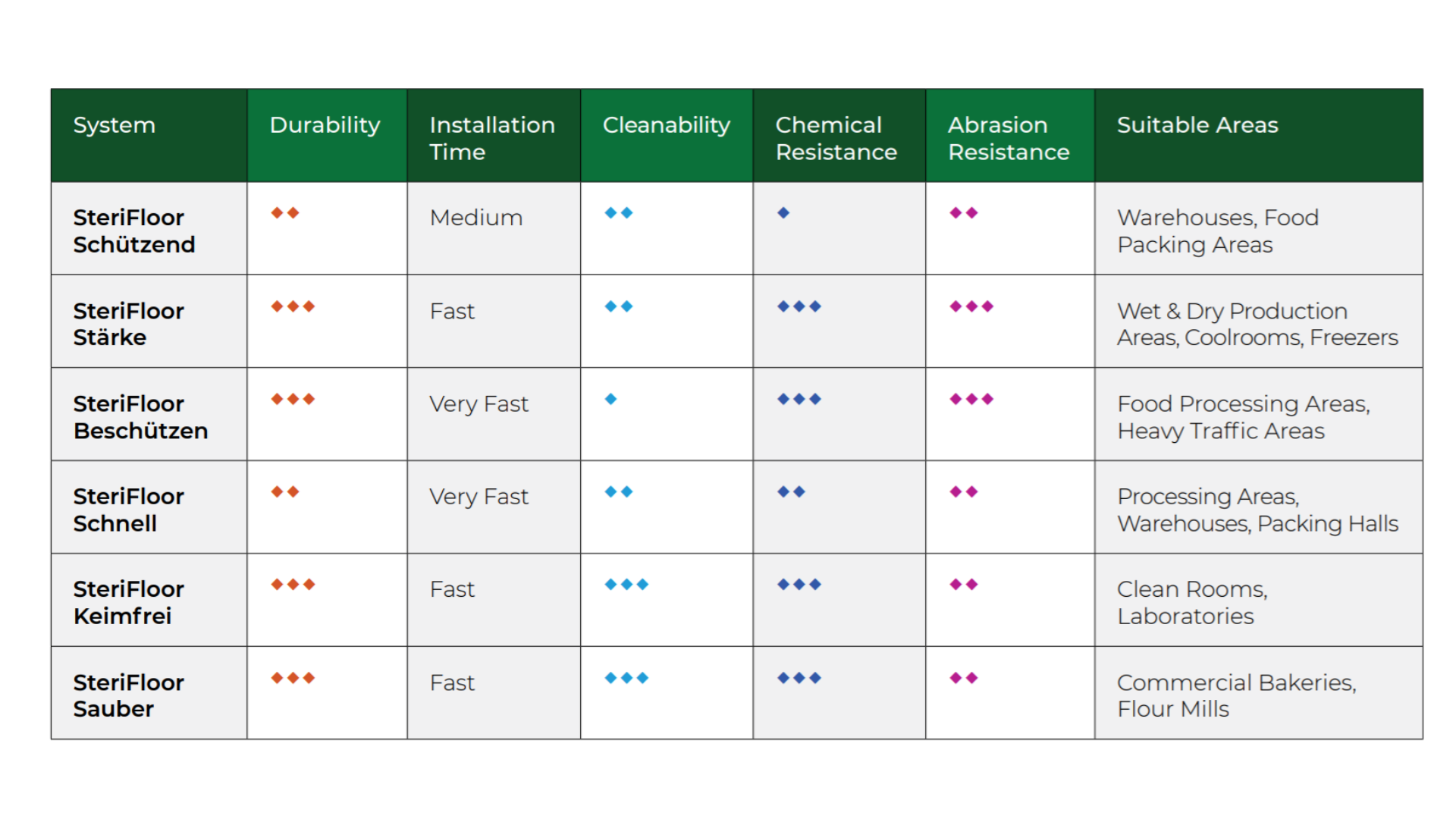

Find the right SteriFloor solution

Our SteriFloor solutions have been designed and manufactured specifically with the Food Manufacturing industry in mind. While not mentioned in the below table, two of these solutions are Epoxy Resin solutions. As set out below, we recommend them only for the particular areas listed below. SteriFloor Keimfrei and SteriFloor Schützend are our two epoxy solutions. All of the others are polyurethane cement systems.

For more information about our SteriFloor solutions, check out this link